-

Business India

| November, 16, 2022“Going beyond carbon”- Santosh Singh and Kavya Hari, Intellecap featured in Business India’s Special Climate Edition, Nov 2022 Issue (Print)

Read More -

Business India

| November, 16, 2022Intellecap Santosh Kumar Singh, Managing Director and Venkata Kotamaraju, Director CAIF featured on Business India’s special climate November 2022 edition

Read More -

inc42

| November, 13, 2022Why Venture Capitalists are doubling down on the Impactech sectors: Bikram Mahajan, Intellecap featured on Inc42

Read More -

agfundernews.com

| November, 02, 2022Good Food Innovation Fund’s first cohort gets USD $1 Million to make better food accessible to Africans- AgFunder Network in conversation with William Mulehi from Intellecap Africa

Read More -

IMPACTENTREPRENEUR

| October, 13, 2022Watch the Videos of Aavishkaar Group Leadership at Impact Investor’s Council “Prabhav 2022”

Read More -

impactentrepreneur

| September, 30, 2022Announcing the Winners of the 14th Edition of the Sankalp Global Awards 2022

Read More -

Hindu Business Line

| September, 20, 2022The 14th Sankalp Global Summit 2022 will rally Global leaders to create transformational impact

Read More -

Good Food Innovation Fund

| September, 07, 2022Good Food Innovation Fund Awards its 1st Cohort of Enterprises with over USD 1 Million to Support Nutritious and Affordable Food Across Sub Saharan Africa

Read More -

Mongabay

| August, 11, 2022Rethinking, recycling and re-loving: A peek into India’s circular fashion economy- Mongabay India features Circular Apparel Innovation Factory

Read More - Agri Farmer Centre (Agriface)from Rwanda, which is working to provide fortified whole grain to schools through a government feeding program

- Muteesa Companyfrom Rwanda, providing post-harvest services and technologies to farmers to help them access high-value markets

- NatureLock Foods, a Kenyan supplier of dried, nutritious foods

- Keep it Cool, a Kenyan company providing solar-powered refrigeration solutions to minimize food waste for farmers and food vendors

- Sanku, a Kenyan company that installs a ‘Sanku dosifier’ onto flour mills, a device that adds a precise ratio of critical nutrients to flour

- Shalem Investments, a Kenyan company that provides smallholder farmers with services and inputs, then buys their produce to sell to predetermined markets

- Smart Logistics Solutions, a Kenyan producer of bean-based products such as noodles and porridges, that have been fortified with zinc and iron.

- Kenya: Fibered Fresh Partners, Keep it Cool, Sanku Kenya Ltd, Shalem Investments, and Smart Logistics Solutions

- Rwanda: Agri Farmer Centre Ltd (Agriface) and Muteesa Company Ltd

- The global fashion industry largely follows the linear pathway of ‘take, make, wear and throw’, producing a staggering 13 million tonnes of global textile waste.

- Textile industry stakeholders are now finding inventive solutions to make the circular fashion economy resilient, restorative and regenerative in nature. An overhaul in the legacy business structures would require an incremental approach that is both planet and people-positive.

- In India, the movement for circular fashion focuses on designing circular textile waste models, unlocking green jobs, setting up technology-backed systems that enables brands to run their thrift shops and solving the price conundrum of slow fashion.

“Going beyond carbon”- Santosh Singh and Kavya Hari, Intellecap featured in Business India’s Special Climate Edition, Nov 2022 Issue (Print)

Mumbai 16th Nov– Santosh Singh, Managing Director and Kavya Hari, Manager, Intellecap was featured in Business India’s Special Climate , Edition, Nov 2022 Issue through an exclusive guest column titled, “Going beyond Carbon” where they talk about new frontiers of sustainability commitments that are yet to be crossed.

The landscape of climate commitments by corporates/ businesses is evolving rapidly, as society and governments accelerate their response to the climate crisis. Globally, 7,000+ corporates/ businesses have pledged to accelerate net-zero as a part of the UN’s ‘race to zero’ campaign and 1,400+ have set science-based net-zero targets verified by the ‘science-based target initiative’ (SBTi). While carbon abatement has been established as the key constituent for mitigating ill-effects of climate change, multiple other associated issues need to be addressed. These include water scarcity, plastic pollution, soil degradation and bio-diversity loss. According to the UN, about a million species are threatened today with extinction but the fact is that the current response to the impending bio[1]diversity loss is insufficient. UNICEF assesses that about two-thirds of the global population experiences severe water scarcity for at least 30 days in a year, while over two billion people live in regions with inadequate water supply. The impact of water scarcity could lead to the displacement of around 700 million people by 2030. Another UN agency, UNEP suggests that up to 200 million tonnes of plastic can be found in our oceans and a projected 23-37 million tonnes could be added every year by 2040.

Emergence of ESG compliance and regulations: Today, business stakeholders, investors and regulators are demanding that companies provide an assessment or report on how their businesses are operating in the context of ESG dimensions. This facilitates them to make informed decisions by identifying corporates/businesses prone to risks and/or underperforming on various environmental metrics compared to those adopting sustainable practices. The investors also expect climate commitments to be science-based and linked to the core business strategy of the corporates/ businesses. As of date, more than 270 investors, with $61.3 trillion in assets under management, have signed a pledge with the ‘net-zero investors’ initiative’; to support the goal of net-zero emissions by 2050.

There are various principles, frameworks and standards that are guiding the ESG reporting. They include ‘global reporting initiative’ (GRI), ‘carbon disclosure project’ (CDP), ‘task force on climate[1]related financial disclosures’ (TCFD), SASB standards, ‘international integrated reporting framework’ and ‘international sustainability standard board’ (ISSB). Emerging markets have also ramped up their efforts in improving ESG standards aligned to global best practices. India has introduced its own business responsibility & sustainability reporting’ (BRSR) framework that is mandatory for top 1,000 companies. This framework intends to set standardised and quantitative disclosures on ESG parameters for corporates/ businesses across sectors. BRSR covers nine core principles — integrity, safety, employee well-being, stakeholder management, human rights, environmental protection, public policy, inclusive growth and consumer engagement to address, which are the key ESG parameters. It is aligned to reporting requirements of TCFD, GRI, CDP and SASB and is inter-operable with most international frameworks. This enables corporates/ businesses already disclosing sustainability reports on these international reporting standards to cross-reference the disclosures required under BRSR.

However, an analysis of the various existing ESG reporting standards and allied corporate climate commitments showcases significant focus on climate mitigation outcomes. The scope here to account for other challenges impeding sustainability is limited indeed.

Focus on carbon plus sustainable benefits: Recent developments such as framework for ‘taskforce on nature-related financial disclosures’ (TNFD), SBTi’s guidelines for forest, land and agriculture (FLAG), ‘guidelines for planning and monitoring corporate bio-diversity performance’ by IUCN, ‘the global commitment and circular economy for plastic use’, led by Ellen MacArthur Foundation – these are all paving the way for carbon plus initiatives. In India, the scope of environment within the BRSR framework also attributes value to environmental/ sustainable outcomes beyond energy and GHG/ scope emissions reporting including aspects like solid waste management, water consumption and withdrawal, sustainable sourcing, 3R (reduce, reuse and recycle), extended producer responsibility (EPR), and life cycle assessments. Further, the BRSR framework is aligned with sustainable development goals (SDGs), thereby promoting corporates/ businesses to demonstrate their performance on achievement of SDGs beyond their climate commitments.

Leveraging the learnings from the growth of carbon market and pricing mechanisms: As corporates/ businesses begin to account for larger sustainable development aligned outcomes, we could witness a rapid shift in the market with monetisation of environmental assets (like water, bio-diversity, plastic, etc) aligned to existing carbon pricing mechanisms. Carbon markets have been helping corporates/ businesses to meet their carbon goals. The rise in net-zero targets and car[1]bon neutrality goals by corporates/ businesses has driven demand for carbon credits to an unprecedented height; with the voluntary carbon market hitting a record value of $1 billion worth of carbon credits in 2021. More than 60 per cent of the value of transactions are attributed to sectors with significant co-benefits contributing to SDGs (like clean cooking, agriculture, forestry, land use, household devices etc).

The rising focus on sustainable/ environmental outcomes beyond emission reductions has already begun development of new methodologies or labels/ certifications by independent car[1]bon crediting standards and/or new market-based mechanisms. A few examples include ‘plastic waste reduction standard’ by Verra, ‘gender standard’ by WOCAN, ‘circular credits mechanism’ by BVRIO, ‘bio-diversity credits’, etc. This new era of credits for allied segments such as bio-diversity credits, water credits, plastic credits is expected to grow rapidly in the near-term. The trajectory of these credits may be more rapid than that of carbon credits, considering the various lessons that may be applied to the former from the latter. Meanwhile, as the standards and guidelines continue to evolve and be established for the carbon market, the same may be replicated for credits from other segments, thereby shortening the route-to-market. Therefore, businesses and investors must take note of these credits as they will be jostling for capital consumption alongside carbon credits sooner than expected.

Intellecap Santosh Kumar Singh, Managing Director and Venkata Kotamaraju, Director CAIF featured on Business India’s special climate November 2022 edition

View full article

Why Venture Capitalists are doubling down on the Impactech sectors: Bikram Mahajan, Intellecap featured on Inc42

Mumbai, Nov 15th – At the 14th Edition of the Sankalp Global Summit 2022 , one of the main plenary sessions was around the topic, ImpacTech Investing: Dichotomy or Paradigm shift?, led by Bikram Mahajan, Partner, Intellecap Investment Banking Group.

Inc42 in conversation with Bikram featured the story, “Why Venture Capitalists are doubling down on the Impactech sectors” which takes that conversation ahead and highlights how when it comes to investment themes, impact and technology have always been discrete buckets for investors. Bikram also opines on how the belief that VC investing is primarily driven by financial objectives whereas impact investing is only about seeking people and planet outcomes has led to such misconception, and the truth about how impact and technology have never been two unrelated paradigms. Both styles of investing are deeply intertwined and form a continuum rather than a dichotomy.

The Rise And Rise Of Impact & Tech Sectors

A decade ago, it was easy to dismiss the impact sector as a collection of not-for-profit organisations supported by foundations and philanthropies. We’ve come a long way since then, and the for-profit impact sector is now formally recognised around the world, and impact investing is a well-defined asset class.

The global impact AUM crossed $1 Tn across asset classes in 2022. This impact AUM is managed by 3,349 organisations, where fund managers account for the majority of them. Concurrently, the startup sector observed $134 Bn invested in 5,200 startups since 2014 in India and a non-trivial $2.5 Tn in over 100,000 startups worldwide.

A new class of impact startups challenging the traditional impact business models also emerged during the last few years, piggybacking on disruptive innovation, an often quoted and generally accepted investment driver in the mainstream startup sector.

Equipped with state-of-the-art technology, impact startups exhibited the promise of accelerated growth translating into superior impact and investment multiples than their traditional impact counterparts.

A few impact investors also broadened their investment themes to join the bandwagon of investing in technology startups, even considering impact in retrospect on occasion, and a few startups that were ignored by mainstream VC funds went to the extreme of impact washing to seek impact pools of capital.

The Impact Vs. Tech Dichotomy

With 107 unicorns and one of the world’s highest unicorn minting velocities, India has only 11 impact unicorns, with no unicorns in sectors such as agritech or cleantech.

One could argue that asset managers have made unprecedented commitments to impact AUM allocation, fueling its 11% growth since 2016. However, the private markets AUM grew from $5.2 Tn in 2016 to $9.8 Tn in 2021 during the same period at a CAGR of 16%.

The gap widens when we consider that the $4.2 Tn funding required to achieve 17 Sustainable Development Goals by 2030 is just 1.1% of assets held by financial institutions.

The predicament intensifies when we combine this statistic with a survey by JP Morgan and GIIN, which found that over 55% of impact funds deliver at least market rate returns, as well as a study by MSCI, Inc. validating the stylised fact that companies with higher ESG ratings have higher profitability, lower systematic risk and lower tail risk.

Impactech Investing: A New Paradigm

From the perspective of an investor, one way to resolve this seemingly obvious conundrum is to recognise “impact” as an investment approach conspicuously integrated into a fund manager’s investment thesis rather than an asset class. Impact investing, according to the Global Impact Investing Network (GIIN), necessitates intentionality and impact measurement.

Using this globally accepted definition, Intellecap’s digital investment banking team estimated that 40% of the world’s 1,200 unicorns can be classified as Impactech startups.

The truth is impact and technology have never been two unrelated paradigms. Both styles of investing are deeply intertwined and form a continuum rather than a dichotomy. The global ESG transition being extensively embraced by tech giants, unicorns and investors across asset classes demonstrates this phenomenon.

For a startup, impactech is often misconstrued as reluctantly espousing backward fitting impact metrics as an after-thought for enhancing investment worthiness or employing emerging technologies one-dimensionally to deliver impact. Scaling up is an inherent objective of every venture, whether digital or impact, intending to solve a grand challenge.

Impactech is about designing business models from the ground up which leverage both technology and impact as sustainable competitive advantages to achieve scale. The next 3 Bn presents the largest underpenetrated market for digital businesses, whereas impact ventures are transforming their business models for scalability through digital inclusion.

Hence, impactech comprises not only a healthcare company employing technology as an enabler for scale and efficiency but also a deeptech startup exploiting big data and AI/ML to digitise and interpret diagnostic reports.

Analogously, not all edtech startups can be classified as impact and not all enterprisetech startups are non-impact. Perhaps the correct approach is to evaluate each startup with intentionality and a measurement lens, rather than defining impactech as an all-encompassing sector.

The impactech dimension has always been ingrained in the investment thesis across strategies, sectors, and stages. Reclassifying impactech as a distinct and broad-based investment theme would simplify investments at the intersection of impact and technology to empower digital businesses that solve global challenges.

Good Food Innovation Fund’s first cohort gets USD $1 Million to make better food accessible to Africans- AgFunder Network in conversation with William Mulehi from Intellecap Africa

Nairobi, 3rd Nov– The Good Food Innovation Fund (GFIF) has selected seven enterprises that are revolutionizing the availability and affordability of ‘good food’ in low-income communities in Kenya and Rwanda to receive funding and technical assistance to expand their operations. The seven SMEs will receive funding between USD 100,000 to 200,000 each, for a total of over USD 1 million.

Launched in 2021 with a USD 5 million grant from The Rockefeller Foundation, the Good Food Innovation Fund supports SMEs to expand access to nutritious and affordable food across sub-Saharan Africa while mitigating barriers such as high prices, consumer preferences, and unfavorable policies. The fund is managed by Intellecap Advisory Services.

Recently AgFunder Network, a reputed Global news network spoke to William Mulehi, Principal, Intellecap Africa on the Good Food Innovation Fund’s 1st Cohort of Winners.

Kenya’s Good Food Innovation Fund (GFIF) recently unveiled the seven companies participating in its first cohort.

As the name suggests, “good food” is the focus area for this first cohort. GFIF designates regenerative, nutritious, and sustainably and equitably produced food as good food. The fund’s goal is to make such foods more widely available and affordable in Sub-Saharan Africa by supporting companies that grow, distribute and provide that food.

The fund, which is managed by social-impact focused advisory firm Intellecap, was started in 2021 with a $5 million grant from the Rockefeller Foundation.

The seven SMEs selected from 144 applications include:

The cohort will receive financial backing of up to $1 million, with startups each getting a sum ranging from $100,000 to $200,000. A lower threshold of $50,000 is in consideration due to the small size of the companies and their ability to properly manage the funds.

Beyond financing, the fund will provide technical support on creating financial models and growth projections. It will also help companies stream line their operations and teams to get them investor ready.

Regional focus

Africa has the highest share of people suffering from food insecurity in the world, according to the United Nations. Roughly 21% of people on the continent suffered from hunger in 2020, or 282 million people. On the other side of the malnutrition scale, Africa is home to 24% of the world’s overweight children aged under 5, according to the World Health Organization.

Initially, GFIF’s call for applications cast a net on Kenya, Rwanda and Burundi, where Rockefeller was already running projects. This first cohort complements existing projects in these countries and targets institutional feeding programs, such as suppliers of fortified whole grain to schools and hospitals.

Apart from their focus on enabling access to good food, companies were chosen based on their potential impact and the uniqueness of their ideas.

“They’re the ones that were really speaking into what the project aims,” William Mulehi, an associate vice president of business consulting and research at Intellecap, tells AFN.

“There’s also a portfolio mix in terms of the impact these organizations are looking at, because we have some that have very high potential to scale and to reach the numbers that we are targeting.”

The project also aims to positively shift food policies in the select countries. For example, Agriface is pushing for fortification of food. While this fortification of staples like vegetable oils, wheat and maize flour is mandatory in Kenya, the case is voluntary for food producers in Rwanda, hence the push from the Rwandese SME.

“We are trying to support these companies with the hope that our intervention is going to have a ripple effect, in terms of policy and policy development,” says Mulehi.

Market nuances

Increasing access to good food also means increasing support for SMEs in fairly young markets.

Consider Burundi. While it’s a focus for GFIF, companies from there didn’t make the cohort owing to the country’s smaller market in comparison to Kenya and Rwanda.

“We didn’t really get strong applications from Burundi,” Mulehi says. “However, we are holding information sessions in Bujumbura [Burundi’s capital], just to take potential companies through the application process of what is required as we try to understand the market nuances in this particular country, which may have had an effect on the low uptake from the companies there.”

Though it’s not supporting the GFIF’s project directly, Burundi’s division of the World Food Programme also helped in drumming up support to get the companies to participate in the sessions. GFIF is now collecting data to tailor its upcoming call for the next cohort, making it suitable for Burundi’s SMEs to get accepted and access the fund’s support.

“In some of these markets, you need to ensure your efforts are complemented,” explains Mulehi. “WFP does a lot of institutional feeding to schools and such settings. So we are working together because there’s an overlap in our mandate. Also for them being on the ground, they have experience in terms of the type of organizations that are in the market and what sort of support that they require.”

Future cohorts

The GFIF will announce the call for its next cohort in November, widening the list of countries to include Ghana and Benin. This time, the innovation in focus will be on vertically integrated solutions such as logistics, post-harvest processing, distribution and retail.

“Our intervention should be able to go a long way in de-risking these companies, for them to be able to access new markets which they would otherwise not be able to venture into maybe due to the perceived risk,” Mulehi notes.

Watch the Videos of Aavishkaar Group Leadership at Impact Investor’s Council “Prabhav 2022”

Impact Investors Council hosted the fourth edition of Prabhav on the 12th and 13th of September in New Delhi. More than 650+ delegates and 140+ speakers across 15 countries graced Prabhav, including over 30 global impact investors. For more on Prabhav – click here

Aavishkaar Group, a founding member of Impact Investors Council, was well represented by Sushma Kaushik, Partner, Aavishkaar Capital & Sowmya Suryanarayanan, Director- Impact and ESG, Aavishkaar Capital who spoke at the Summit while Amar Gokhale, Associate Director- Gender & Livelihoods, Intellecap, and Sanchayan Chakravorty, Partner, Aavishkaar Capital moderated key sessions at the Summit.

Equity For Impact | Sector Insights: Financial Inclusion

Financial Inclusion has been the traditional mainstay of India’s impact investing ecosystem, attracting almost half the entire equity capital flowing into Indian impact enterprises since 2017. This panel explored how India’s financial inclusion landscape has evolved over the years and highlighted the tech-driven innovative business models propelling this sector into the future.

Speakers: Ajaita Shah, Founder And CEO, Frontier Markets – Anirudh Sarda, Head of Equity Investments (Asia), Oikocredit – Jyotsna Krishnan, Managing Partner, Elevar Equity – Sanjay Jain, Chief Innovation Officer, CIIE.CO – Shashaank Awasthi, India Advisor, Gray Ghost Ventures, Sushma Kaushik, Partner, Aavishkaar Capital

To watch the Video – Click Here

Impact Measurement and Management: Practitioner’s Perspective

Impact measurement and management helps create systemic, sustainable change and also drives value creation for all stakeholders. A robust impact measurement and management framework enables enterprises and investors to account for their social performance, value their contribution to society and generate greater credibility with stakeholders such as their customers. It is therefore critical to develop universal standards for social impact to catalyze the scaling up of the impact investing ecosystem.

Speakers: Arnab Mandal, Functional Head – Impact Measurement, Tata Trusts, Devang Bhandari, Global COO – ESG Advisory, KPMG, Reihem Roy, Partner, Omnivore Sowmya Suryanarayanan, Director – Impact and ESG, Aavishkaar Capital, Sugandhi Matta, Chief Impact Officer, ABC Impact – Varad Pande, Partner – Strategy, Impact & New Initiatives, Omidyar Network India

To watch the Video –Click Here

The Road Ahead for Climate Investing: Experiences & Learnings from LPs

This session brought together Global and Indian Climate-tech Capital Providers to draw best practices and learnings from the global climate-tech ecosystem. The discussion focused on the pathways to strengthen a few climate-tech sectors in India and accelerate deployment of low-carbon affordable technologies across industries.

Speakers: Ankit Agrawal, Private Equity Professional, Neev Fund – Biswarup Banerjee, Program Manager – Renewable Energy, IKEA Foundation – Priya Shah, General Partner, Theia Ventures, Sanchayan Chakraborty, Partner, Aavishkaar Capital and Tarun Arora, Partner, Encourage Capital.

To watch the Video – Click Here

Building a conducive ecosystem for gender lens investing: voices from the ground

This panel discussion explored the size of the investment and social impact opportunity for India using a gender-responsive strategy. The discussion unearthed key challenges for impact funds while charting out interventions (short-term as well as long-term) required to bolster gender equity in the impact investing ecosystem in India. This session was curated by Value for Women.

Speakers: Amar Gokhale, Associate Director, Gender + Livelihoods, Intellecap, Jenaan Lilani, Chief Operating Officer, Villgro Innovations Foundation – Ragini Bajaj Chaudhary, Director – Investments, Caspian Impact Investment Advisers – Ranjna Khanna, Director, Impact Investors Council, Shaila Lee, Global Vice-President, HR, Husk Power Systems.

To watch the Video –Click Here

Announcing the Winners of the 14th Edition of the Sankalp Global Awards 2022

Mumbai, September 30, 2022: Powered by Sankalp Forum, an initiative of Intellecap, the 14th Sankalp Global Summit hosted the annual Sankalp Global Awards 2022, geared to support, reward, recognize and celebrate high impact enterprises from around the world that are tackling key development challenges.

This year, impact enterprises from 43 countries applied to the coveted awards, with the winners chosen by a jury panel composed of eminent business leaders and global investors. The top 7 winners of the Sankalp Global Awards 2022 include Aloi from Nepal in the Financial Inclusion category, Bandhu from India in the Livelihoods and Future of Work(ers) category, Equatorial Power from Democratic Republic of the Congo in the Clean Energy and Climate Solutions category, Solinas from India in the Health & WaSH category, Numer8 from India in the Agriculture category, Tvasta Manufacturing from India in the Affordable Housing category and Essmart from India which won the Sankalp Ecosystem Award through a unique voting process by the impact community.

Each of the winners are solving complex social challenges through cutting-edge innovations and high potential entrepreneurship, with each demonstrating the ability to scale, disrupt and bring transformative impact in their sector.

The winner in the Financial Inclusion category, Aloi from Nepal is a micro-entrepreneur financing platform that uses blockchain to automatically monitor business expenditures

The winner in the Livelihoods and Future of Work(ers) category, Bandhu from India is a mobile platform that enables low-income workers to simultaneously line up accommodation and livelihood by providing each potential migrant with a package consisting of a job and associated rental housing.

The winner in the Clean Energy and Climate Solutions category, Equatorial Power from Democratic Republic of the Congo, is a decentralized energy infrastructure company, focused on its services of building and operating solar hybrid mini-grids to provide essential power for 20 years.

The winner in the Health & WaSH category, Solinas from India, is a deep-tech startup providing asset management solutions leveraging robotics for the pipeline and sanitation industry, solving problems of water leakages, and eliminating manual scavenging.

The winner in the Agriculture category, Numer8 from India, helps small-scale fishing community by providing hourly updated marine and weather advisory, backward and forward market linkages, and financial connections by using their app.

The winner in the Affordable Housing category, Tvasta Manufacturing from India, provides 3D Printing as a mainstream solution for affordable housing, automating construction, and improving productivity and sustainability in the industry to provide better infrastructure to millions around the world.

The winner of the Sankalp Ecosystem Award 2022, selected through a unique voting process, instituted for the impact community, Essmart from India is a curated B2B e-commerce platform for rural retail shops that specializes in products that transform rural revenue potential and improve livelihoods, enabling them to sell products that struggle to move through existing supply chains and grow their businesses.

“Sankalp Global Awards brings together impact entrepreneurs to help solve challenges through cutting-edge innovation and high potential entrepreneurship. Sankalp Awards, today, in its 14th year, highlighted transformative ideas that will define the next decade, thereby demonstrating our ability to drive action and influence outcomes,” said Urvashi Devidayal, Sankalp Lead, India.

Some of the key renowned speakers at the Summit included Global leaders and practitioners such as Wendy Werner, Country Head, International Finance Corporation (IFC), Ambassador Gurjit Singh and Smt. Lakshmi Puri, Former Ambassadors of India, Ugo Astuto, Ambassador of the European Union to India, Delegation of the European Union, Ms. Ina Hagniningtyas Krishnamurthy, Ambassador Extraordinary and Plenipotentiary of the Republic of Indonesia to India, Freddy Svane, Ambassador Of Denmark, Sandeep Chakravorty, Joint Secretary, Ministry of External Affairs, Dr. Indu Bhushan, Former CEO, Ayushman Bharat, Abhishek Gopalka, MD & Partner, Boston Consulting Group, Zaved Akhtar, CEO & MD, Unilever Bangladesh, Dr. Rajat Chabba, Senior Technical Advisor, Global Healthcare Innovations at Jhpiego, Indu Bhushan, Former CEO, Ayushman Bharat (National Health Authority), Dennis Curry, Deputy Resident Representative, UNDP, Ashish Desai, Director, NITI Aayog, Payal Dayal, Senior VP, Mastercard, Sivakumar Surampudi, Group Head – Agri & IT Business, ITC, Anjalli Ravi Kumar, Chief Sustainability Officer, Zomato, Professor Dr. Rohit Jindal, MacEwan University School of Business, Monika Frech, MD, Yunus Social Business, Luis Noda, VP, Habitat for Humanity, Dr. Ajay Mathur, Director General, International Solar Alliance (ISA), Shereen Bhan, Managing Editor CNBC –TV18, Ajaita Shashidhar, Editor At Large, Fortune India, Govindraj Ethiraj, Editor, IndiaSpend, Swati Khandelwal, Executive Editor, Zee Business and Varsha Meghani, Principal Correspondent, Forbes India, among several others.

To know more, please visit – https://www.sankalpglobalsummit.com/

The 14th Sankalp Global Summit 2022 will rally Global leaders to create transformational impact

Mumbai, September 23, 2022: The 14th Sankalp Global Summit 2022 will be held virtually from 27-29 September 2022, and will bring unparalleled innovation, learning, and networking with entrepreneurs and impact leaders from across the world. The convening, hosted by Sankalp Forum, an Intellecap initiative, will be attended by over 3,000 global delegates from 100 + countries and will feature 160 Global Speakers, 40 Sessions, 200 Hours of Learning and 120 Hours of Networking across 9 High Impact tracks.

Global leaders and practitioners attending the Summit include Wendy Werner, Country Head, International Finance Corporation (IFC), Gurjit Singh and Lakshmi Puri, Former Ambassadors of India, Ugo Astuto, Ambassador of the European Union to India, Zaved Akhtar, CEO & MD, Unilever Bangladesh, Payal Dayal, Senior VP, Mastercard, Sivakumar Surampudi, Group Head – Agri & IT Business, ITC, Anjalli Ravi Kumar, Chief Sustainability Officer, Zomato, Professor Dr. Rohit Jindal, MacEwan University School of Business, Monika Frech, MD, Yunus Social Business and Luis Noda, VP, Habitat for Humanity, Shereen Bhan, Managing Editor, CNBC- Young Turks, Ajita Sashidhar, Editor At Large, Fortune India, Swati Khandelwal, Executive Editor, Zee Business and Luis Noda, VP, Habitat for Humanity, among several others.

The theme for this year’s Sankalp Global Summit is #TransformingImpact and is a clarion call for the impact community to embrace “entrepreneurship, collaboration and empathy” to navigate a changing world dynamic, with a view to deliver on the UN Sustainable Development Goals (SDGs) by 2030.

The summit will showcase 10 outstanding Global Startup Finalists through the Sankalp Global Awards 2022. As the Oscars of the Development Sector, the Awards are an opportunity for promising entrepreneurs to showcase their innovative solutions that can help transform vulnerable communities.

CEO of Intellecap, Vikas Bali, said, “The world has changed beyond our imagination. We are faced with a looming climate crisis having recorded the hottest summer in history, while the pandemic and an ongoing war have disrupted economic growth, wiping out years of developmental progress, and pushing millions into poverty. Our focus has to shift towards creating a collective response that will embrace fundamental shifts in our thinking and bring to bear, interconnectedness, empathy and transformational change, and galvanize plans to action. At Sankalp discover compelling insights to broaden the scale and build a sustainable, equitable society through ideas and investments that drive impact.“

Some of the Key Partners for the Summit this year include UNDP, Jhpiego, Terwilliger Center for Innovation in Shelter, IDRC and Energy Catalyst. The Summit is also supported by over 40+ Friends of Sankalp, Media and Outreach Partners.

This year the Summit will host Intellecap’s Rendezvous, the Private Mid-Market Companies Conference that brings together Entrepreneurs and Global Investors.

Sankalp India Lead, Urvashi Devidayal said, “The time is now to bring about transformational impact and a renewed thinking that spurs economic growth in an inclusive, sustainable manner, while helping us achieve the ambitious SDG Goals. We will leverage the Sankalp platform to enable meaningful connections between entrepreneurs, capital providers and the larger developmental ecosystem. Join us at Sankalp to reshape the future.”

The Summit will also host conversations centered around ‘High Impact tracks’ that focus on the different areas of work of the impact investment community. These include Inclusive Fintech & Financial Services, Healthcare, Water & Sanitation, Gender Lens Investing & Women Leadership, Agriculture, Climate Change & Clean Energy, Impact Investing, Blended Finance, Collaborative Philanthropy and Affordable Housing.

Join us at the 14th Edition of the Sankalp Global Summit 2022. The time for transformational change is today and we are saving you a seat. For more info and to register for the event, please visit – https://www.sankalpglobalsummit.com/

Using Climate Tech for Achieving Net Zero & Resilience

Mumbai, 14th Sept: The Impact Investing Handbook 2022 is a multidimensional view on enabling social impact. This 144 page handbook provides a comprehensive guidance on the landscape of Impact Investing in India and positions impact investing as a multi-faceted approach to catalyzing different scales of social impact in India and brings in analytical insights on key market trends and investment opportunities through seven focus areas: Equity Impact Investing, Debt Impact Investing, Gender-Lens Investing, Climate-tech Investing, Blended Finance, Sourcing of Capital for Impact and Policy & Regulations.

The Handbook, a pioneering initiative by Impact Investors Council (IIC) in collaboration with The British Asian Trust was launched at ‘Prabhav 2022’ in New Delhi. Aavishkaar Capital

The article, Using Climate Tech for Achieving Net Zero & Resilience has been exclusively written for the handbook by Sanchayan Chakraborty, Partner, Aavishkaar Capital and Santosh Singh, MD, Intellecap, under Climate-tech investing and as part of the ‘Voices of Industry’ section of the handbook.

Climate change is already resulting in, and is projected to increasingly cause, huge disruptions on economic activities, ecological systems and societal wellbeing. To mitigate the worst climate impacts, greenhouse gas emissions must be halved by 2030 and reach ‘Net-zero’ by 2050 from current levels according to the Intergovernmental Panel on Climate Change. This recognition has led to increased focus by both countries and corporations, on mitigation of climate risks and adaptation towards climate change. Globally, 77 parties representing 84 countries have pledged a net zero target covering 73% of global GHG emissions as per Climate Watch’s Net-Zero Tracker. In addition, 5000+ businesses have announced their own net-zero commitments under the UN’s Race to Zero campaign. Fulfillment of these climate commitments, encompassing both reduction of emissions and improving resilience to climate change, will require wide-ranging investments in climate technology development, building of green and climate smart infrastructure and transformation of business processes.

The imperative of climate change mitigation has been highlighted by UNFCC for over 4 decades. Multilateral climate talks led to the Kyoto Protocol in 1997 (effective from 2005), under which 37 developed countries made commitments to reduce their emissions, developed methodologies for measurement of emissions and offsets, thereby paving the way for the first national and regional markets for carbon credits. Significant venture capital investments (more than US$ 25 bn) were also made in climate technologies between 2006 and 2011, mostly in clean energy technologies in solar and wind, which were seen to be the priorities at that time. However, limited participation in the global GHG reduction commitments (none by developing nations) and shifting strategic priorities of obligated countries led to continued lack of progress in global climate talks. Global carbon markets eventually collapsed by 2012 and economic incentives for climate tech development reduced, resulting in many of the ventures losing money.

The current global decarbonization efforts are however comprehensive, encompassing all sectors of the economy and benefit from a broader and more robust agenda. This is evidenced by the fact, (a) global climate talks are progressing well under the Paris Agreement, which now includes both developed and developing economies, (b) carbon markets are well established in many economies, and (c) increased frequency of extreme weather events has spurred stakeholder activism pushing the private sector to make voluntary commitments (in addition to regulatory requirements) towards net-zero. Climate tech start-ups deploying low-carbon technologies and promoting carbon sequestration will need to play a big role in achieving transition to net-zero emissions at scale. Climate tech investments have seen a five-fold rise between 2016 and 2021 to reach $40 billion. In the first half of 2022, climate tech start-ups had already raised ~$19 billion from 500 VC funded rounds. More than 80% of the investment flows were to US and Europe, while Asia Pacific accounted for around 10%.

India is particularly vulnerable to climate change, given that a large section of its population lives near climate thresholds, is dependent on agriculture and other nature-based resources, and has low per capita income, thereby limiting ability for adaptation. Climate policies as well as climate innovation effort so far in India have primarily focused on mitigation solutions through solar and wind energy generation and de-carbonization of industry due to the high carbon footprint of these sectors; a lot more can and needs to be done on building adaptation and climate resilience. Between 2016 and 2020, 200 Indian climate tech start-ups raised more than USD1.2 billion in venture capital. Bulk of the investments were drawn to mitigation focused solutions in sustainable mobility (59%) and energy (25%), in line with global trends. Only 12% contributed to climate smart agriculture and natural resources and 4% to circular economy and waste management. The scale of the climate crisis necessitates the need to drive sustained decarbonization of the Indian economy across all sectors, including industry, food and agriculture, natural resources and built environment besides energy and transportation where bulk of the innovation efforts are focused at this time. The climate tech investment landscape would need to evolve towards funding deep decarbonization technologies to achieve its net zero target by 2070, while also investing in resilience building to further reduce climate risks

Aavishkaar Capital’s approach to funding climate tech innovations has been geared towards climate adaptation across agriculture and industry, which can impact livelihoods of, and risks to, the low-income population, at scale. Some of our earliest investments were in energy access and efficiency technologies like Vortex, which makes solar powered ATMs for rural India, and Servals, which makes energy efficient cookstove burners. Waste management is of serious concern in India which Aavishkaar identified as a theme and invested in Saraplast, which runs a portable toilet service for construction sites and urban areas, and in Lets Recycle, which is one of the largest dry waste recycling start-ups in India, currently handling around 600 MT/day across 5 cities. Aavishkaar’s investment in Soulfull was directed at climate adaptation in agriculture by promoting millets, which are climate and livelihood friendly grains traditionally grown in India

Globally, while mobility solutions (electric transportation, green hydrogen, battery) and energy transition (non-fossil fuel energy generation, grid tech, storage tech) continue to see the largest venture activity, the climate tech investment landscape has broadened to include • Food systems (land use management, alternative proteins, regenerative agriculture, alternative fertilizers) • carbon tech (carbon sequestration, climate/earth data analytics, carbon capture, carbon accounting) • clean industry tech (circular economy, fuel alternatives, emissions capture), and • Built environment (heating/cooling, advanced materials, energy/water efficiency). Across all of these sectors, use of data analytics, AI/ML, blockchain and robotics/ drones are driving many decarbonization innovations Approx. 30% of climate tech funding globally in H1 2022 is estimated to have been in carbon tech, climate management and built environment; carbon tech specifically pulled in US$ 1.5 bn in funding (more than 3X of 2021).

We at Aavishkaar believe that a holistic view of the impact of climate change on the earth’s systems and society needs to be taken, with the goals being multifarious and not just focused on emissions reduction. Venture activity needs to focus on enhancement of climate resilience and providing transition support to the communities most likely to be affected by climate change, compensating providers of ecosystem services (of air, water, forests, grasslands), protection/augmentation of the stock of natural assets and protection of biodiversity. The carbon markets are one such example that price the emissions and allow for building of natural ecosystems and compensation to the ecosystem builders, with positive impact across climate, community and biodiversity. We are excited about the Indian entrepreneurial innovations which seek to address these challenges/markets and will continue to actively invest in climate tech innovations that have the potential to materially impact India’s and global decarbonization with resilience pathway.

Good Food Innovation Fund Awards its 1st Cohort of Enterprises with over USD 1 Million to Support Nutritious and Affordable Food Across Sub Saharan Africa

Kigali, Rwanda, 7th Sep– The Good Food Innovation Fund (GFIF) has selected seven enterprises that are revolutionizing the availability and affordability of ‘good food’ in low-income communities in Kenya and Rwanda to receive funding and technical assistance to expand their operations. GFIF received 144 applications for this initial call for applications. Selection focused on small and medium enterprises (SMEs) with a special interest in promoting nutritious, regenerative, and equitably produced and distributed food—called “good food”—through schools and other institutional feeding programs. The seven SMEs will receive funding between USD 100,000 to 200,000 each, for a total of over USD 1 million.

Launched in 2021 with a USD 5 million grant from The Rockefeller Foundation, the Good Food Innovation Fund supports SMEs to expand access to nutritious and affordable food across sub-Saharan Africa while mitigating barriers such as high prices, consumer preferences, and unfavorable policies. The fund is managed by Intellecap Advisory Services.

SMEs selected to receive support in this initial round of support include:

These SMEs have been selected at a time of growing food insecurity globally. In 2021, more than 282 million Africans were undernourished, and the ongoing Covid-19 pandemic, climate change, and the Russia-Ukraine conflict have fueled further food price hikes—making access to affordable food even more difficult and threatening to send millions more into hunger.

“African businesses have a vital role to play in making sure that people, especially in low-income communities, have to access nutritious and affordable food,” said Mehrdad Ehsani, Vice President at The Rockefeller Foundation. “Supporting them will improve efficiencies along the food supply chain, reduce the cost of production, increase their competitiveness, and enable them to reach to low-income populations with nutritious food.”

One of the recipients, Agriface, will work with its distributors to provide fortified wholegrain maize flour to school children through the government’s school feeding program in Rwanda. It is also promoting equitable production and distribution systems by sourcing directly from farmers while paying fair prices for their produce.

Smart Logistics Solutions, another award recipient, is a Kenyan enterprise leading in production of nutrient dense foods that are beans based. They have developed a variety of bean-based products such as noodles, and fortified porridges using beans fortified with iron and zinc. Designing such products ensure that the children and youth can enjoy foods that are attractive to them but are more nutritious and affordable. With the additional financing they will be able to reach an additional 20 schools and 25 hospitals.

“The Fund is a novel way for SMEs to improve access to affordable and nutritious foods. We are excited to work with these selected enterprises,” said Karnika Yadav, Partner & Director – Africa, Intellecap. “We are eager to help discover and transform their innovative ideas into real benefits for health and nutrition of low-income communities across Africa, while strengthening the ecosystem for good food.”

The Good Food Innovation Fund will launch its second innovation call in October 2022. This call will target innovations in vertically integrated value chains with distribution and retail, harvest and post-harvest, processing, distribution, and logistics, and will cover the additional countries of Ghana and Benin.

For more information about the GFIF, visit: Good Food Innovation Fund

Rethinking, recycling and re-loving: A peek into India’s circular fashion economy- Mongabay India features Circular Apparel Innovation Factory

Recently Mongabay India carried a detailed story around India’s circular fashion economy with inputs from key ecosystem players who are making an impact.

The story titled, “Rethinking, recycling and re-loving: A peek into India’s circular fashion economy” features insights from Venkat Kotamaraju, Director, CAIF and highlights Circular Apparel Innovation Factory’s extensive work in the space.

In the recent years, the textile industry has been the subject of criticism for its negative environmental and societal impacts, which have only grown, owing to fast fashion and the culture of fashion influencers. The greenhouse emissions of the global textile industry are known to be greater than all international flights and shipping combined. It is considered to be one of the largest polluting industries after food and construction, and its supply chain needs an urgent makeover.

However, the industry’s transition to building a sustainable ecosystem cannot be achieved overnight. The business models have been following a linear pathway of ‘take, make, wear and throw’, for several years; producing a staggering 13 million tonnes of global textile waste that ends up in landfills or is burned.

Delhi-based fashion label Doodlage collects post-consumer waste for segregation, to help Indian shoppers responsibly discard the clothes they no longer want. Photo from Doodlage.

According to anthropological estimates, the history of clothing dates back to 100,000 – 500,000 years, with animal fur and natural materials such as grass and leaves, primarily playing the role of the modern-day fabric. The humble beginnings were followed by a series of innovations, making clothing and fashion a visible expression of social identity.

Today, the fashion industry employs over 300 million people across the value chain, on a global scale. In India, the sector provides direct employment to over 45 million and 100 million people in allied industries. The statistics indicate that an overhaul in the legacy business structures would require an incremental approach that is both planet and people-positive.

The statistics have injected a slow, but rising dose of consciousness among industry stakeholders, who are now finding inventive solutions that are building the foundations of a circular fashion economy, one that is resilient, restorative and regenerative in nature.

Building an ecosystem of green micro-entrepreneurs

Mumbai-based Circular Apparel Innovation Factory (CAIF) – an initiative by Intellecap supported by the DOEN Foundation – describes itself as an ecosystem-builder, accelerating the transition of the apparel and textile industry towards circularity. The people at CAIF primarily work at two levels: First, they create a pipeline of innovations for brands, helping them achieve their 2030 sustainability goals to reduce carbon footprint. Second, their focus is on building an ecosystem and designing circular textile waste models that aim for closing the leakage loop.

In November 2021, they partnered with sustainability innovators Enviu and IKEA Foundation, to build capacities and skills among India’s informal waste workers, in order to unlock green jobs among the marginalised communities.

CAIF has been actively working with over 20 Indian and global brands through different pilot projects and initiatives creating ‘green micro-entrepreneurs’. Photo from CAIF.

CAIF has been actively working with over 20 Indian and global brands through different pilot projects and initiatives creating ‘green micro-entrepreneurs’. Photo from CAIF.

“In the absence of an organised system that would help us identify and trace where these waste collectors take the waste from factories and households, we asked ourselves some basic questions – ‘How can we leverage their current understanding of the waste ecosystem?’, ‘Can we give them access to knowledge, capital, network and solutions?’” Venkat Kotamaraju, Director, CAIF and Climate Solutions, Intellecap, told Mongabay-India.

With the intention to create an organised pathway for textile waste collection, the cohort has launched area-specific pilot projects in Mumbai and Bengaluru. The focus predominantly is on training waste workers in sorting post-consumer waste and aiding them to become “green micro-entrepreneurs”, who are informed to identify the difference between repairable, reusable and worn-out clothing.

Kotamaraju said that currently, waste workers are not formally trained to identify the composition of the fabric. “They usually sell secondhand clothes and factory waste in kilos. We are imparting skills that help them identify that the value of a torn t-shirt is not the same as denim. When they understand the monetary value of the garment and direct it towards the right recyclers or cloth aggregators, we reduce the leakage of wastage into the environment.” He adds that eventually, the idea is to set up hyper-local collection and segregation centres for both manufacturers and consumers to bring circularity within reach.

For this, CAIF works closely with anchor partners – Hasiru Dala and Sahas Zero Waste in Bengaluru and Aasra Welfare in Mumbai, respectively. These partners identify waste collectors in these areas, who are then trained on various aspects of material integrity. So far, a group of 38 waste collectors have been trained. CAIF aims to increase the number to 250 workers in the first phase, creating a framework where the waste is collected in a responsible manner.

Building authenticity in the secondhand clothing market

As the former CEO of the fashion brand Okhai, Kirti Poonia is credited for scaling its business operations and building a community of artisans, especially women. However, during this process, she also identified the problem of overfilled wardrobes, largely owing to changes a woman’s body undergoes. “An average woman goes through 31 body changes in her lifetime,” said Poonia.

While it was just one part of the problem, the other was the environmental impact of fast fashion on the planet. Realising that the problems in the fashion industry were systemic and multidimensional, she felt the need to find a capitalistic solution to social or environmental problems, because that makes it easier for brands to adopt.

Relove works to build authenticity in the thrifting process and establishes direct partnership with brands. Photo from The Summer House.

Her solution to fashion pollution came in the form of Relove – a technology-backed system that enables brands to run their thrift shops. Poonia, along with her partner and co-founder Prateek Gupte launched the platform on Instagram in November 2021, with one fashion brand on board. In a span of nine months, they have partnered with 30 brands.

What makes Relove stand out, is their direct partnership with brands, which allows buyers an authentic history of the garment.

“We are building authenticity in the thrifting process that is otherwise marred by ambiguity,” Poonia said. “No one knows the origin, source or owner of the garments that are being sold in the name of secondhand fashion.”

Reselling a garment enhances its lifespan. According to Gupte, every time a garment is resold, it saves “six times its weight in CO2”. “You are eliminating the entire cycle of producing a product that is resource-intensive,” he says.

Underlining the change in perception, especially among Gen Z, Gupte shares that they receive orders from across the country, reflecting a growing acceptance of secondhand clothing culture in the country. “Our average selling time of a pre-loved garment is six days,” he added. The authenticated business model surely makes a strong business case, considering this segment is expected to reach $64 billion within five years.

The pricing conundrum in circular fashion

Not all brands have a resale policy. Neither does India have a robust system of textile waste collection. However, India has been a recycling hub for textiles for several decades and is also one of the lead importers of used clothes. While the latter has only contributed to the existing burden of clothing wastage in India, the recycling factories have been the feedstock of several sustainable brands. One of them is the Delhi-based fashion label Doodlage, which has been converting upcycled factory waste into limited edition collections since 2012. Their recent initiative involves –collecting post-consumer waste for segregation to help Indian shoppers responsibly discard the clothes they no longer want.

Doodlage upcycles factory waste into limited edition collections. Photo from Doodlage.

Doodlage upcycles factory waste into limited edition collections. Photo from Doodlage.

While Doodlage arguably has the first-mover advantage in the sustainable fashion industry, the one question they were repeatedly asked in the initial years was of pricing: Why were their clothes made of waste so steeply-priced?

The conundrum of higher unit pricing especially for all sustainable brands limits their outreach to a larger consumer base in India, whose fashion choices are still driven by several e-commerce websites and brands that are selling fast fashion at a cheap cost. “The price tag attached to slow fashion labels is the true price of slow production, which is better for people producing products and the planet,” said Kriti Tula, co-founder and creative director of Doodlage.

Meanwhile, Kotamaraju examines the puzzle of pricing through the economics of demand and supply, highlighting that the affordable cost of fast fashion is a result of scaled operational models, off-shore manufacturing and low-cost labour, among others.

“The unit pricing is fundamentally the reason why scaling the circular economy is critical,” he said. “However, because of a complex value chain, the adoption of sustainable practices is slower. For a company whose infrastructure is designed for a cotton economy, switching to an alternative, more sustainable material would add up to the cost.”

To read this story on Mongabay India– Click Here

Reports & Policies

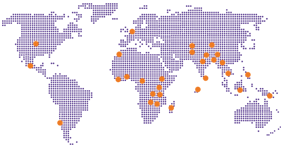

Our Impact Map

Sign up for our newsletter

© Copyright 2018 Intellecap Advisory Services Pvt. Ltd. - All Rights Reserved