Rethinking, recycling and re-loving: A peek into India’s circular fashion economy- Mongabay India features Circular Apparel Innovation Factory

Recently Mongabay India carried a detailed story around India’s circular fashion economy with inputs from key ecosystem players who are making an impact.

The story titled, “Rethinking, recycling and re-loving: A peek into India’s circular fashion economy” features insights from Venkat Kotamaraju, Director, CAIF and highlights Circular Apparel Innovation Factory’s extensive work in the space.

In the recent years, the textile industry has been the subject of criticism for its negative environmental and societal impacts, which have only grown, owing to fast fashion and the culture of fashion influencers. The greenhouse emissions of the global textile industry are known to be greater than all international flights and shipping combined. It is considered to be one of the largest polluting industries after food and construction, and its supply chain needs an urgent makeover.

However, the industry’s transition to building a sustainable ecosystem cannot be achieved overnight. The business models have been following a linear pathway of ‘take, make, wear and throw’, for several years; producing a staggering 13 million tonnes of global textile waste that ends up in landfills or is burned.

Delhi-based fashion label Doodlage collects post-consumer waste for segregation, to help Indian shoppers responsibly discard the clothes they no longer want. Photo from Doodlage.

According to anthropological estimates, the history of clothing dates back to 100,000 – 500,000 years, with animal fur and natural materials such as grass and leaves, primarily playing the role of the modern-day fabric. The humble beginnings were followed by a series of innovations, making clothing and fashion a visible expression of social identity.

Today, the fashion industry employs over 300 million people across the value chain, on a global scale. In India, the sector provides direct employment to over 45 million and 100 million people in allied industries. The statistics indicate that an overhaul in the legacy business structures would require an incremental approach that is both planet and people-positive.

The statistics have injected a slow, but rising dose of consciousness among industry stakeholders, who are now finding inventive solutions that are building the foundations of a circular fashion economy, one that is resilient, restorative and regenerative in nature.

Building an ecosystem of green micro-entrepreneurs

Mumbai-based Circular Apparel Innovation Factory (CAIF) – an initiative by Intellecap supported by the DOEN Foundation – describes itself as an ecosystem-builder, accelerating the transition of the apparel and textile industry towards circularity. The people at CAIF primarily work at two levels: First, they create a pipeline of innovations for brands, helping them achieve their 2030 sustainability goals to reduce carbon footprint. Second, their focus is on building an ecosystem and designing circular textile waste models that aim for closing the leakage loop.

In November 2021, they partnered with sustainability innovators Enviu and IKEA Foundation, to build capacities and skills among India’s informal waste workers, in order to unlock green jobs among the marginalised communities.

CAIF has been actively working with over 20 Indian and global brands through different pilot projects and initiatives creating ‘green micro-entrepreneurs’. Photo from CAIF.

CAIF has been actively working with over 20 Indian and global brands through different pilot projects and initiatives creating ‘green micro-entrepreneurs’. Photo from CAIF.

“In the absence of an organised system that would help us identify and trace where these waste collectors take the waste from factories and households, we asked ourselves some basic questions – ‘How can we leverage their current understanding of the waste ecosystem?’, ‘Can we give them access to knowledge, capital, network and solutions?’” Venkat Kotamaraju, Director, CAIF and Climate Solutions, Intellecap, told Mongabay-India.

With the intention to create an organised pathway for textile waste collection, the cohort has launched area-specific pilot projects in Mumbai and Bengaluru. The focus predominantly is on training waste workers in sorting post-consumer waste and aiding them to become “green micro-entrepreneurs”, who are informed to identify the difference between repairable, reusable and worn-out clothing.

Kotamaraju said that currently, waste workers are not formally trained to identify the composition of the fabric. “They usually sell secondhand clothes and factory waste in kilos. We are imparting skills that help them identify that the value of a torn t-shirt is not the same as denim. When they understand the monetary value of the garment and direct it towards the right recyclers or cloth aggregators, we reduce the leakage of wastage into the environment.” He adds that eventually, the idea is to set up hyper-local collection and segregation centres for both manufacturers and consumers to bring circularity within reach.

For this, CAIF works closely with anchor partners – Hasiru Dala and Sahas Zero Waste in Bengaluru and Aasra Welfare in Mumbai, respectively. These partners identify waste collectors in these areas, who are then trained on various aspects of material integrity. So far, a group of 38 waste collectors have been trained. CAIF aims to increase the number to 250 workers in the first phase, creating a framework where the waste is collected in a responsible manner.

Building authenticity in the secondhand clothing market

As the former CEO of the fashion brand Okhai, Kirti Poonia is credited for scaling its business operations and building a community of artisans, especially women. However, during this process, she also identified the problem of overfilled wardrobes, largely owing to changes a woman’s body undergoes. “An average woman goes through 31 body changes in her lifetime,” said Poonia.

While it was just one part of the problem, the other was the environmental impact of fast fashion on the planet. Realising that the problems in the fashion industry were systemic and multidimensional, she felt the need to find a capitalistic solution to social or environmental problems, because that makes it easier for brands to adopt.

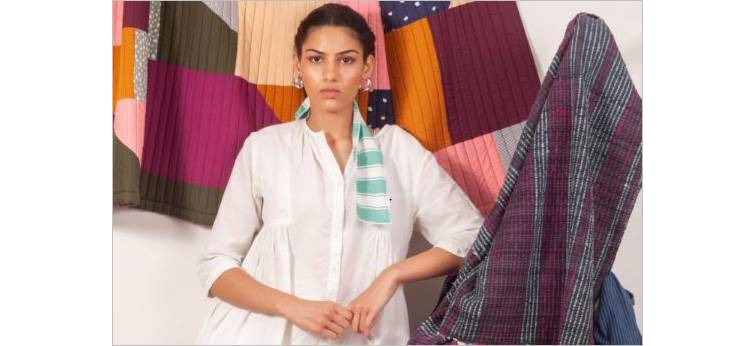

Relove works to build authenticity in the thrifting process and establishes direct partnership with brands. Photo from The Summer House.

Her solution to fashion pollution came in the form of Relove – a technology-backed system that enables brands to run their thrift shops. Poonia, along with her partner and co-founder Prateek Gupte launched the platform on Instagram in November 2021, with one fashion brand on board. In a span of nine months, they have partnered with 30 brands.

What makes Relove stand out, is their direct partnership with brands, which allows buyers an authentic history of the garment.

“We are building authenticity in the thrifting process that is otherwise marred by ambiguity,” Poonia said. “No one knows the origin, source or owner of the garments that are being sold in the name of secondhand fashion.”

Reselling a garment enhances its lifespan. According to Gupte, every time a garment is resold, it saves “six times its weight in CO2”. “You are eliminating the entire cycle of producing a product that is resource-intensive,” he says.

Underlining the change in perception, especially among Gen Z, Gupte shares that they receive orders from across the country, reflecting a growing acceptance of secondhand clothing culture in the country. “Our average selling time of a pre-loved garment is six days,” he added. The authenticated business model surely makes a strong business case, considering this segment is expected to reach $64 billion within five years.

The pricing conundrum in circular fashion

Not all brands have a resale policy. Neither does India have a robust system of textile waste collection. However, India has been a recycling hub for textiles for several decades and is also one of the lead importers of used clothes. While the latter has only contributed to the existing burden of clothing wastage in India, the recycling factories have been the feedstock of several sustainable brands. One of them is the Delhi-based fashion label Doodlage, which has been converting upcycled factory waste into limited edition collections since 2012. Their recent initiative involves –collecting post-consumer waste for segregation to help Indian shoppers responsibly discard the clothes they no longer want.

Doodlage upcycles factory waste into limited edition collections. Photo from Doodlage.

Doodlage upcycles factory waste into limited edition collections. Photo from Doodlage.

While Doodlage arguably has the first-mover advantage in the sustainable fashion industry, the one question they were repeatedly asked in the initial years was of pricing: Why were their clothes made of waste so steeply-priced?

The conundrum of higher unit pricing especially for all sustainable brands limits their outreach to a larger consumer base in India, whose fashion choices are still driven by several e-commerce websites and brands that are selling fast fashion at a cheap cost. “The price tag attached to slow fashion labels is the true price of slow production, which is better for people producing products and the planet,” said Kriti Tula, co-founder and creative director of Doodlage.

Meanwhile, Kotamaraju examines the puzzle of pricing through the economics of demand and supply, highlighting that the affordable cost of fast fashion is a result of scaled operational models, off-shore manufacturing and low-cost labour, among others.

“The unit pricing is fundamentally the reason why scaling the circular economy is critical,” he said. “However, because of a complex value chain, the adoption of sustainable practices is slower. For a company whose infrastructure is designed for a cotton economy, switching to an alternative, more sustainable material would add up to the cost.”

To read this story on Mongabay India– Click Here

View full article