Building the supply chain infrastructure for a Circular Apparel industry

Mumbai, 13th February –Siddharth Lulla, Principal, Circular Apparel Innovation Factory (CAIF), Intellecap was recently featured on the Times of India blogs through his article, “Building the supply chain infrastructure for a Circular Apparel industry” which highlights how CAIF is working with upstream supply chain partners primarily SMEs to reduce carbon emissions,

Under the aegis of UN Climate Change, brands and retailers worked during 2018 to identify ways in which the broader textile, clothing and fashion industry can move towards a holistic commitment to climate action. As a result, industry players made bold commitments to enable circularity, reduce 45% emissions by 2030 and achieve net-zero by 2050. Initially these commitments were focused on Scope 1 and Scope 2 emissions, which are produced by the companies directly or through the purchase of energy. However today, most companies have pledged to reduce their Scope 3 emissions generated in the upstream and downstream value chain. This is a crucial step since, for many companies, Scope 3 accounts for 80% of their overall climate impact.

Given the scale of the problem, it is imperative to set ambitious targets and implement a well thought approach to deliver on them. Achieving net-zero for Scope 1 and Scope 2 themselves requires overcoming formidable economic and technical challenges. Scope 3 presents an additional layer of complexity such as aligning internal stakeholders on goals and milestones; working collaboratively with supply chain partners, customers; keeping all partners engaged in multiyear change efforts; non-transparent carbon accounting and tracking mechanisms.

An in-depth assessment through in-person consultations with Textile & Apparel (T&A) stakeholders, which included industry leaders such as H&M, IKEA, Marks and Spencer and their manufacturing partners, and learning’s from our initiatives have identified key gaps that need to be addressed to develop the supply chain infrastructure for circular and net-zero apparel:

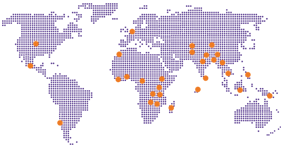

Hence Intellecap, through its initiative Circular Apparel Innovation Factory (CAIF), is working with upstream supply chain partners primarily SMEs to reduce carbon emissions, through testing, validating and commercial adoption of circular and low-carbon solutions in resource efficiency (energy, water), alternate materials (low-carbon dyeing alternatives, etc.), and from recovering value from waste (fiber2fiber recycling). Based on our learnings, we believe that four steps need to be followed by organizations that are committed to multiplying their own efforts and decarbonizing the supply chain through supplier engagement. They are:

Research findings have indicated that existing solutions which include renewable electricity, sustainable materials and processes, alternate fuels, etc., have the potential to reduce supply chain carbon emissions by 47%. However, for the balance there is a need to test, validate and adopt innovative technologies and business models such as next generation materials, waterless dyeing, dry processing just to name a few. In order to address this, through our ongoing initiatives we have successfully worked towards building a strong business case for low carbon / circular supply chain solutions available in India. Project ACE, a two-year program (2021-2023), designed as a common action platform with the singular purpose of establishing a business case (economic value creation for the private sector organizations while reducing their environmental footprint). To create a robust business case, CAIF designed demonstration pilots with multiple stakeholders (brands and their manufacturing partners) to test, validate and commercially deploy high potential low-carbon solutions in areas including energy efficiency, water efficiency, alternative dyes and chemicals, digital solutions in textiles waste traceability, etc.

In the last 12 months alone, we have undertaken six pilots and delivered the below outcomes:

(work to measure the impact on carbon footprint is currently in process)

According to our private sector partners, three key aspects were critical in design /execution of the pilots along with expediting the buy-in from leadership / board teams for eventual long-term commercial contracts:

Hence based on these learnings we believe there is a need for and are working towards designing long term transformation programs with brands and their supplier networks to lay the foundation of a circular supply chain infrastructure and catalyze their journey to NetZero.

View full article